Automotive

The cutter of bullmer get your products at their best.

No matter which technology you need, bullmer has the right cutting technology for you.

In the field of interior design bullmers Procut high ply cutter offers the right performance. Up to 80 mm (depending on material) the Procut cuts textiles, laminated fabrics or artificial leather and a good deal more….if required in 24/7 mode.

Different features have proved themselves and have been adjusted to the customer needs – with customers who know what they want – Quality, Output and Highest Uptime!

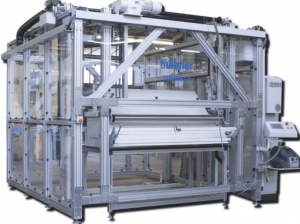

For cutting of car carpets the Premiumcut single ply cutter is the right choice. With its robust construction and the variety of combinations and a possible working width up to 5 m the Premiumcut cuts car mats and floor carpets straight from the roll

Additional options as a scanning system (for repeat recognition) and unwinding units for heavy rolls with big diameters will support the processing large or heavy rolls such as laminates.

Environmental aspects have become more and more important today, by reducing vehicle weight the emissions will be lowered. That’s why the low weight production becomes more and more important.

Sample Configuration:

Interior:

| Working width from 1.800 mm to 2.200 mm |

|---|

| cutting window length von 1.800 mm – 4.200 mm (other measurements on request) |

| Driven unwinding unit for plastic foil |

| Procut D 8001 – Multilayer cutting machine up to 80 mm compressed |

| Vacuum unit (e.g. 17,5 kW) |

| Oscillating knife |

| Recommendation of spreading machine: Compact E 600 or E 2000 |

Carbon Fiber Multilayer cutting

| Working width from 1.800 mm to 2.800 mm |

|---|

| cutting window length von 1.800 mm – 4.200 mm (other measurements on request) |

| Driven unwinding unit for plastic foil |

| Turbocut D 2501 – Multilayer cutting machine up to 25 mm – depending on material |

| Vacuum unit 17,5 kW |

| Oscillating knife |

| Carbon dust protection orientated from IP 60 |

| Recommendation of spreading machine: Compact E 1100 Option: Labeling |

Carpet

| Working width from 1.400 mm to 5.000 mm |

|---|

| cutting window length von 1.200 mm – 3.200 mm (other measurements on request) |

| Double roller unwinding unit or Special unwinding unit SAV 300D |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit 7,5 kW |

| Automatic vacuum chamber sectioning |

| Drag knife |

Leather

| Working width from 1.800 mm to 2.800 mm |

| 3 or 4 zone system |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 2 x 7,5 kW) Automatic vacuum chamber sectioning |

| Electric oscillating knife Electric rotary knife |

| Drill Module Notch Module |

| Pen Module |

| Leather Nesting Solution: RG Technologies Beamer solutions and automated solution |

Prepreg

| Working width from 1.400 mm to 2.800 mm |

|---|

| cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Unwinding device AWV1-S3 |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 4,0 kW) |

| Drag knife |

| Option: Ultrasonic module |

| Option: Labeling Ink Jet Module |

Dry carbon and glasfiber single ply cutting

| Working width from 1.400 mm to 2.800 mm |

|---|

| cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Driven unwinding unit AWV-A |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 4,0 kW) |

| Electric rotary knife |

Optional:

Your time advantage by exchanging the material rolls:

Material Roll Magazine „Transroll-P“ in combination with the unwinding unit AWV-A with

center drive.

Other unwinding units depending on material type and material characteristics are available as well.