Graphics

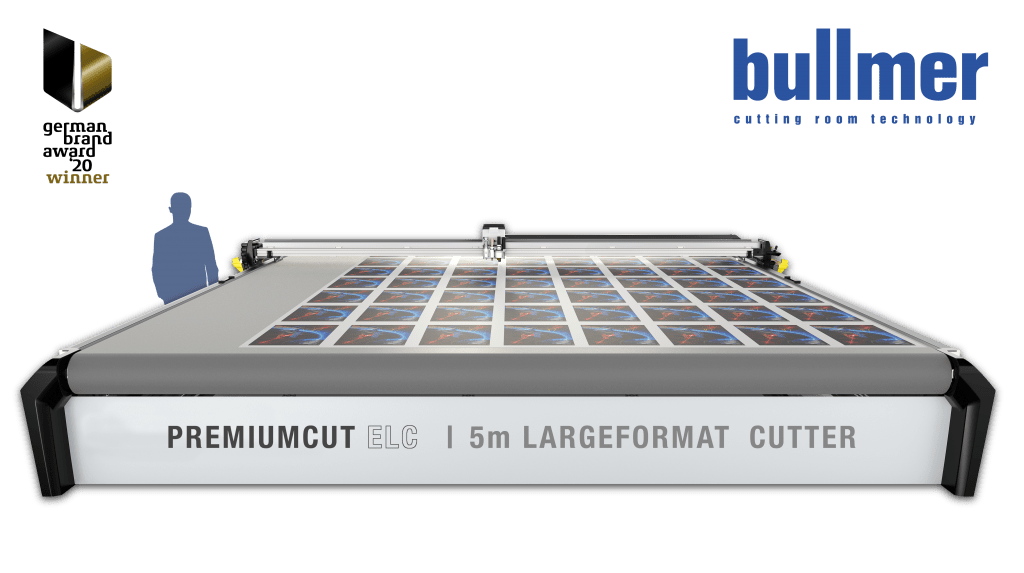

Unmistakably bullmer – the 5m wide Premiumcut

Textiles, Banner, PVC, Vinyl, Mesh, Carpet, etc.

Increase the output with the unique 5 m wide single ply cutting system Premiumcut.

With the modular tool system and the remarkable solidity of bullmer machines you will convince your customers with a professional variety. In combination with the optical recognition software system Optiscout the best possible cutting performance will be achieved.

Strong and Efficient – the Premiumcut

With its modular tool system the Premiumcut is equipped for any graphics finishing. Whether cutting, v-cut, creasing, kisscut or milling – the Premiumcut rules its métier. Even with strong materials the 2.1 kW milling spindle won´t have any problem. And the pneumatic bit-exchange makes tool change easy. Materials like Carton, Acryl, Aludibond, or MDF and others are processible with the suitable tool.

The Premiumcut is available in different working width from 1.400 mm to 5.000 mm.

Additional to the standard table length (1.200 mm, 2.000 mm, 2.500 mm und 3.200 mm) individual table length are available.

In combination with the optical recognition software system Optiscout the best possible cutting performance will be achieved.

Picture:

Cutting system Premiumcut with 2.1 kW milling spindle (max. 60.000 U/min) with pneumatic bit-exchange and integrated suction hose in the cutting beam plus Electric powered rotary knife.

Sample Configuration:

5 m Super-wide

| Working width 5.000 mm |

|---|

| Cutting window length 3.200 mm (other measurements on request) |

| Special unwinding unit SAV 300 D |

| PREMIUMCUT ELC – Conveyor |

| Automatic vacuum chamber sectioning |

| Vacuum unit (e.g. 7,5 kW) |

| Drag knife |

| Electric powered rotary knife |

| Optiscout Software |

Textile

| Working width from 1.600 mm to 5.000 mm |

|---|

| Cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Special Unwinding unit SAV 300 D |

| PREMIUMCUT ELC – Conveyor |

| Automatic vacuum chamber sectioning |

| Vacuum unit (e.g. 7,5 kW) |

| Drag knife |

| Electric powered rotary knife |

| Optiscout Software |

Milling

| Working width form 1.400 mm to 3.200 mm |

|---|

| Cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Double roller unwinding device |

| PREMIUMCUT ELC – Conveyor |

| Automatic vacuum chamber sectioning |

| Vacuum unit (e.g. 7,5 kW) |

| Dragknife |

| Electric oscillating knife |

| 2.1 kW milling spindle (max. 60.000 U/min) with pneumatic bit-exchange and integrated suction hose in the cutting beam |

| Optiscout Software |

All-in-One

| Working width form 1.400 mm to 5.000 mm |

|---|

| Cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Special Unwinding unit SAV 300 D |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 7,5 kW) Automatic vacuum chamber sectioning |

| Drag knife, Creasing wheel Electric oscillating knife Pneumatic oscillating knife |

| Electric powered rotary knife V-Cut with adjustable cutting angle 15° – 22,5° – 30° – 45° – 60° |

| Optiscout Software |

Optional:

Your time advantage by exchanging the material rolls:

Material Roll Magazine „Transroll-P“ in combination with the unwinding unit AWV-A with center drive.

Other unwinding units depending on material type and material characteristics are available as well.