Upholstery

The Premiumcut cuts plain fabrics and patterned fabrics straight from the roll, this allows efficient nesting saving expensive upholstery fabric.

In combination with the well proven leather system from RG Technologies the Premiumcut forms a technically matured leather system. Whether half or complete hides – the Premiumcut cuts reliably and correctly. Leather prices rise and skilled labour is scarce, the Premiumcut optimizes leather use and uses skilled labour productively – look forward to significant savings and perfect cutting quality.

If you offer both leather and fabrics the sales mix will change week by week and the Premiumcut is capable of cutting both.

Option:

Scanner system for automatic recognition of pattern repeat for patterned fabrics, this copes with bow, skew and repeat variations in patterned fabrics.

Sample Configuration:

Textile

| Working width 1.400 mm to 5.000 mm |

|---|

| cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Unwinding unit AWV-A with centre drive and edge alignment |

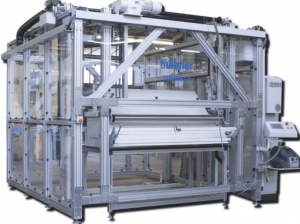

| PREMIUMCUT ELC – Conveyor |

| Automatic vacuum chamber sectioning |

| Vacuum unit (e.g. 7,5 kW) |

| Electric rotary knife |

| Notch Module Drill Module |

| Pen Module |

| Optional: Material Handling system Transroll-P |

Multilayer cutting

| Working width 1.800 mm to 2.200 mm |

|---|

| cutting window length 1.800 mm; 2.500 mm and 4.200 mm (other measurements on request) |

| Driven unwinding unit for plastic foil |

| Procut D 8001 CV – Multilayer cutting machine |

| Vacuum unit (e.g. 17,5 kW) |

| Oscillating knife |

| Recommendation of spreading machine: Compact E 600 or E 1700 / E1800 |

| Option: Labeling |

Leather

| Working width 1.800 mm to 2.800 mm |

|---|

| 3 or 4 zone system |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit with (e.g. 2 x 7,5 kW) Automatic vacuum chamber sectioning |

| Electric oscillating knife Electric rotary knife |

| Drill Module Notch Module |

| Pen Module |

| Leather Nesting Solution: RG Technologies Beamer solutions and automated solution |

Optional:

Your time advantage by exchanging the material rolls:

Material Roll Magazine „Transroll-P“ in combination with the unwinding unit AWV-A with

centre drive.

Other unwinding units depending on material type and material characteristics are available as well.