Composites

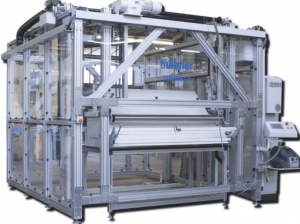

For processing of dry fiber-reinforced composites and fiberglass the Turbocut D 2501CV multilayer cutting system is the best way to cut in volume. In combination with the spreading machine Compact E 1100 which was especially developed for technical textiles bullmer offers a complete processing system which meets high approval in practice.

For processing and combination of dry fiber-reinforced composites, UD, films, foams, honeycombs and Prepreg the single ply cutter Premiumcut is the best choice. With its exchangeable tools and the ultrasonic module the Premiumcut is all-purpose ply cutter suitable for any composite.

For marking of the parts an inkjet printer, a labeler or various pen markers are available as an option. Carbon dust protection orientated on IP 60 is also available.

Sample Configuration:

Dry carbon and Glass Fibre Multilayer cutting

| Working width 1.800 mm to 2.800 mm |

|---|

| cutting window length 1.800 mm; 2.500 mm and 4.200 mm (other measurements on request) |

| Driven unwinding unit for plastic foil |

| Turbocut D 2501 CV – Multilayer cutting machine |

| Vacuum unit (e.g. 17,5 kW – controllable) |

| Oscillating knife |

| Carbon dust protection orientated from IP 60 |

| Recommendation of spreading machine: Compact E 1100 Option: Labeling |

Prepreg

| Working width 1.400 mm to 2.800 mm |

|---|

| Cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Unwinding device AWV1-S3 |

| PREMIUMCUT ELC – Conveyor Carbon dust protection orientated from IP 60 |

| Vacuum unit (e.g. 4,0 kW) |

| Drag knife |

| Option: Ultrasonic module Labeling Ink Jet module |

Dry carbon and fibreglass single ply cutting

| Working width 1.400 mm to 2.800 mm |

|---|

| Cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Driven unwinding unit AWV-A |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 4,0 kW) |

| Electric rotary knife |

| Carbon dust protection orientated from IP 60 |

Optional:

Your time advantage by exchanging the material rolls:

Material Roll Magazine „Transroll-P“ in combination with the unwinding unit AWV-A with center drive.

Other unwinding units depending on material type and material characteristics are available as well.