Apparel

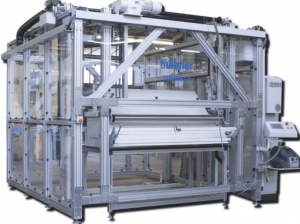

In combination with the suitable spreading machine the Procut’s effectiveness is enhanced.

In the sample department and for small orders or special measure garments the Premiumcut single ply cutter is a good alternative. Through its high speed you process your material single ply straight from the roll of fabric.

Pattern matched fabrics, such as checks and stripes, are cut accurately by the Premiumcut in combination with the bullmer scanning system.

The advantage: With the Premiumcut single ply cutter you do not have to use a plastic foil to fix the material on the belt due to the use of electric rotary blade and notch tool.

It is also possible to save energy costs by using smaller vacuum pumps.

There is also a big range of unwinding unit which you can choose regarding your material specifications

Sample Configuration:

Textile

| Working width 1.400 mm to 5.000 mm |

|---|

| cutting window length 1.200 mm – 3.200 mm (other measurements on request) |

| Unwinding unit AWV-A with center drive and edge alignment |

| PREMIUMCUT ELC – Conveyor |

| Automatic vacuum chamber sectioning |

| Vacuum unit (e.g. 7,5 kW) |

| Electric rotary knife |

| Notch-Modul Bohr-Modul |

| Pen-Modul |

| Optional: Materiallagersystem TRANSROLL-P |

Multilayer cutting

| Working width 1.800 mm to 2.200 mm |

|---|

| cutting window length 1.800 mm – 4.200 mm (other measurements on request) |

| Driven Unwinding unit for plastic foil |

| Procut D 8001 CV – Multilayer cutting machine |

| Vacuum unit (e.g. 17,5 kW) |

| Stich knife |

| Recommendation of spreading machine: Compact E 600 or E 1700 / E1800 Option: Labeling |

Leather

| Working width 1.800 mm to 2.800 mm |

|---|

| 3 or 4 zone system |

| PREMIUMCUT ELC – Conveyor |

| Vacuum unit (e.g. 2 x 7,5 kW) Automatic vacuum chamber sectioning |

| Electric oscillating knife Electric rotary knife |

| Drill Module Notch Module |

| Pen – Modul |

| Leather Nesting Solution: RG Technologies Beamer solutions and automated solution |

Optional:

Your time advantage by exchanging the material rolls:

Material Roll Magazine „Transroll-P“ in combination with the unwinding unit AWV-A with

center drive.

Other unwinding units depending on material type and material characteristics are available as well.