OptiScout

Optiscout is a software program for importing and editing vector graphics. It has a modular optical recognition software system for industrial cutter systems.

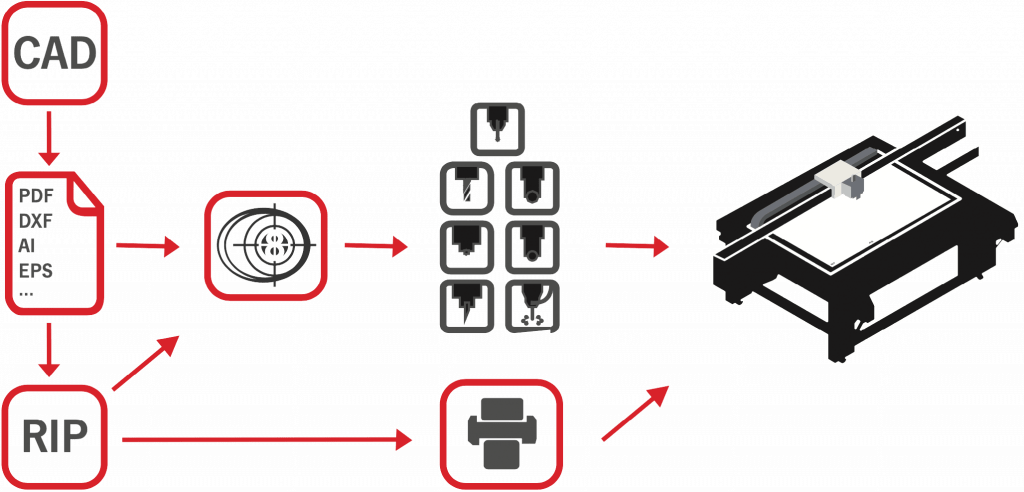

Cut Finishing Workflow

OptiScout accompanies the user step by step through the finishing workflow – be it printed or unprinted materials. Data can be imported via defined interfaces from RIPs, CAD or graphic applications. OptiScout is a cross-platform solution for all cutting or milling applications.

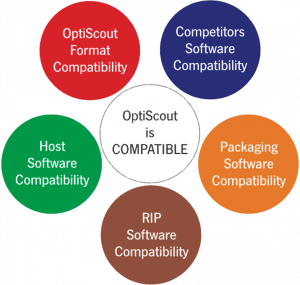

Compatibility

Compatibility is a key factor in integrating finishing

solutions in mixed production environments.

RIP Compatibility*

Supporting RIPs: Agfa Asanti, Aurelon PrintFactory, Cadlink,

Caldera, ColorGATE, EFI, ErgoSoft PosterPrint / TexPrint, IGEPA

MasterRip, ONYX, Pjannto, PosterJet, Prepare-it, SAi, Wasatch

* All trademarks are the property of their respective owners. CAD

Basic Training

[row]

[column md=”6″]

[/column]

[column md=”6″]

[/column]

[/row]

Optional Training

[row]

[column md=”6″]

[/column]

[column md=”6″]

[/column]

[/row]

Front-end module is an import plug-in for CAD software. Optiscout Front-End is recommended as an option for industrial cutting machines.

| Training contents: |

|

| Prerequisites: |

|

| Training duration: | 1 day |

| Graduation: | training certificate |

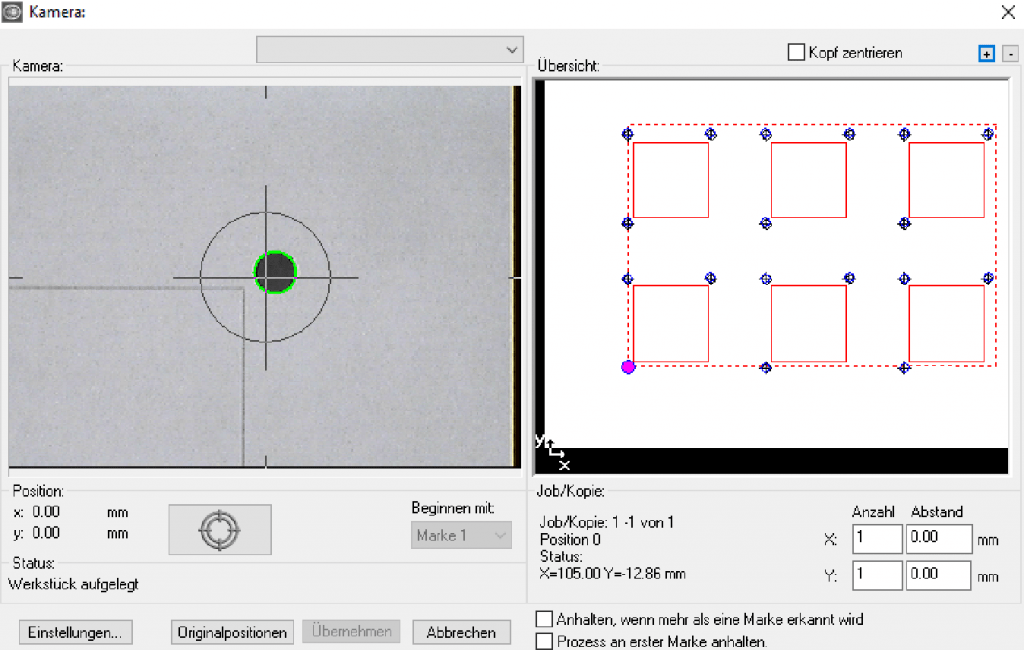

This software is suitable for users who want to cut or mill printed materials with precise contours.

| Training contents: |

|

| Prerequisites: |

|

| Training duration: | 1 day |

| Graduation: | training certificate |

The QR code production profile allows fully automatic cutting/milling of materials printed with the QR code. The camera recognizes the appropriate job files with the help of the QR codes. This allows mixed jobs to be processed on any material.

Individualized series production

| Training contents: |

|

| Prerequisites: |

|

| Training duration: | 1 day |

| Graduation: | training certificate |

Nesting nests object contours on rolls or plates with the aim of consuming as little material as possible.

| Training contents: |

|

| Prerequisites: |

|

| Training duration: | 1 day |

| Graduation: | training certificate |